Open topic with navigation

HVPA/LVPA Motor/Brake Interfaces

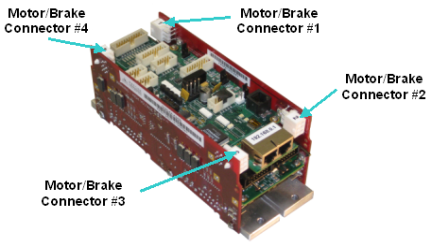

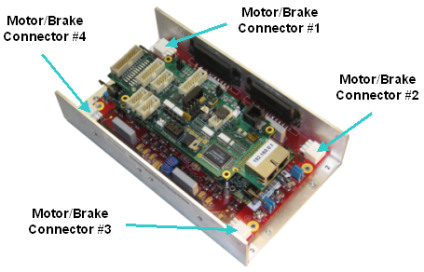

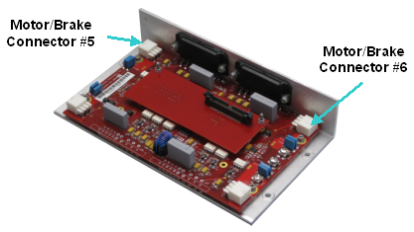

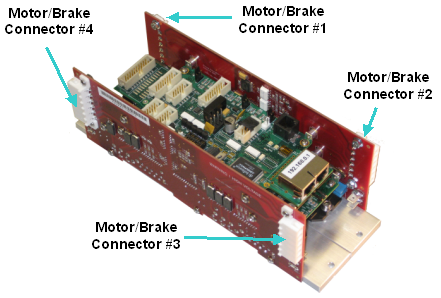

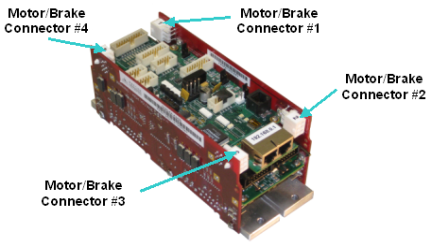

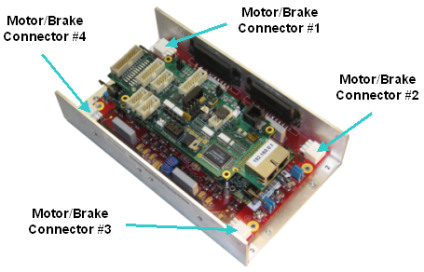

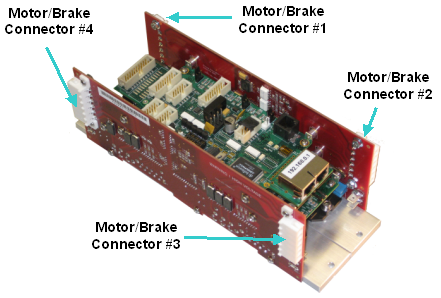

There are identical motor/brake connectors located

on the High Voltage Power Amplifiers (HVPA) of the Guidance 3000 (excluding

the 30A version, see below), the 4-axis High Voltage Power Amplifier

(4AHV) for the Guidance 2000, and the two-Axis Slave High Voltage Power Amplifier (2AHV) for the Guidance 2600. Each

HVPA has two motor drivers per board with two connectors mounted at the top

edge. Each

4AHV has four motor drives with a connector mounted at each corner. Each 2AHV has two motor drives with a connector at each corner of the high side of the sheet metal. These

connectors are numbered on their tops and are illustrated in Figure 11-29, Figure 11-30, and Figure 11-31 for each type

of controller.

|

The High Voltage Power Amplifiers (HVPA/_AHV) and the Motor/Brake

connectors and their leads contain unshielded high voltage pins,

components and surfaces. It

is intended that the Guidance Controllers with these components be

mounted in a cabinet or machine chassis that is not accessible when

AC line power is turned on.

|

|

Figure 11-29: Motor/Brake Connectors

Figure 11-30: Motor/Brake Connector

Figure 11-31: Motor/Brake Connectors

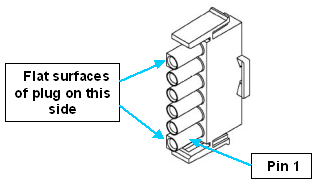

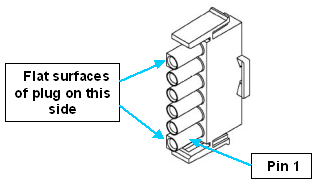

Mating plugs and pins for the motor/brake

connectors are shown below (Figure 11-32 and Table 11-19).

NOTE: Although all of the motor/brake

connectors have a brake signal, this is only provided as a wiring convenience. The

Guidance Controllers turn all brakes on and off at one time, so

independent brake control for each motor is not supported via the dedicated

IO lines available in this connector. If required, individual brake

control can be implemented using general purpose digital output signals.

Figure 11-32: Mating Plug

|

While

many brakes draw less than 0.5A, for some large motors, the current

draw can be much larger. If more than 2A is required for all

brakes, an external relay should be used to separately power the brakes

to avoid damaging the controller.

|

|

Table 11-18: Pinout

| Pin |

Description |

|

1

|

Brake Power 24VDC, maximum current 2A total for all brakes

|

|

2

|

Motor Phase V

|

|

3

|

Motor Phase W

|

|

4

|

Brake Power Return

|

|

5

|

Motor Frame Ground/Cable Shield

|

|

6

|

Motor Phase U

|

|

Board Connector Part No

|

AMP Mini Universal Mate-N-Lok 2 6 pin 770969-1

|

|

User Plug Part No

|

Amp 794190-1 (pins AMP 794231-1)

|

|

User Socket Part No

|

Amp 794231-1 for 16-20 gauge wire

|

|

Crimp Tool

|

Amp 91594-1

|

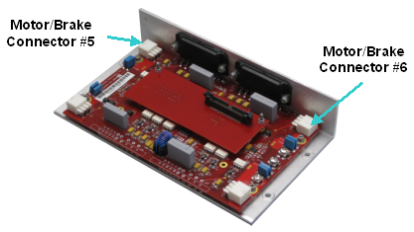

The 30A version

of the Guidance 3400 controller, the Guidance 3430, utilizes a different

motor/brake connector that can support larger gauge wires and higher motor

currents. Each

of the High Voltage Amplifier (HVPA2) boards has two motor

drives and two connectors mounted on the side of the board. Figure 11-33 shows the

numbering for the motor/brake connectors.

Figure 11-33: Numbering for Motor/Brake Connectors

|

The High Voltage Power Amplifiers and the Motor/Brake

connectors and their leads contain unshielded high voltage pins,

components and surfaces. It

is intended that the Guidance Controllers with these components be

mounted in a cabinet or machine chassis that is not accessible when

AC line power is turned on.

|

|

Mating plugs and pins for the motor/brake connectors

are shown in Figure 11-34 and Table 11-19.

NOTE: Although all of the motor/brake

connectors have a brake signal, this is only provided as a wiring convenience. The

Guidance Controllers currently turn all brakes on and off at one time, so

independent brake control for each motor is not supported via the dedicated

IO lines available in this connector. If required, individual brake

control can be implemented using general purpose digital output signals.

Figure 11-34: Mating Plugs & Pins

Table 11-19: Pinout

| Pin |

Description |

|

1

|

Motor Phase W

|

|

2

|

Motor Phase V

|

|

3

|

Motor Phase U

|

|

4

|

Motor Frame Ground/Cable Shield

|

|

5

|

Brake Power Return

|

|

6

|

Brake Power 24VDC, maximum current 2A total for all brakes

|

|

Board Connector Part No

|

Tyco Electronics 640587 Universal Mate-N-Lok

|

|

User Plug Part No

|

Tyco Electronics 640585 6 Circuit Universal Mate-N-Lok

|

|

User Socket Part No

|

AMP 350550-1 for 14-20 gauge wire

|

|

Crimp Tool

|

AMP 90546-1

|