For example, if the mode is "1" and the trigger_pt is "10", if the next motion is joint interpolated, the channel signal will be asserted by the first trigger when the joints are 90% of the way to their final values. Alternately, the same result could be achieved with a mode of "1001". In this case, the second trigger will be utilized. The two triggers per motion are completely independent and identical in their performance.

For modes 4 & 5, the trigger point is computed assuming that the system is operating with the System Speed (as set via the Operator Control Panel) at a value of 100%. If the System Speed is set to 50%, the motion time is doubled and the effective trigger point time is doubled as well. To set the time value to be independent of the System Speed, the trigger_pt value should be adjusted by the value of the "System wide test speed in %" (DataID 601).

If the next motion is blended with the subsequent motion and a mode is selected that is relative to the end of the next motion, the trigger point will be relative to the end of the blending period. Since the start and end of the blending period are a function of both the next and the subsequent motions, the trigger point will vary as a function of both motions. Likewise, if the next motion is blended with the previous motion, trigger points defined relative to the start of the next motion will vary as a function of the motion blending.

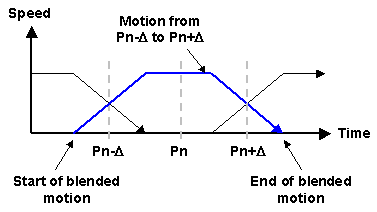

If you desire to trigger a signal when the robot reaches the end point of a motion, but that motion is blended with the subsequent motion, it is possible to trigger at approximately the correct position without regard to the details of the blending algorithms. Specifically, if you wish to trigger when the robot reaches position Pn, create two intermediate positions that are equidistance before and after Pn (Pn minus a small delta and Pn plus a small delta). Then rather than moving to Pn, move to Pn minus the delta and then Pn plus the delta. If you set the trigger to occur 50% of the way through the motion between these two intermediate positions, the signal will trigger when the robot is approximately at Pn. See .

If a motion terminates in the standard manner, the digital output signal or thread event is guaranteed to be asserted at some point during the motion. However, if an error or RapidDecel function prematurely terminates a motion, the trigger may not be asserted.