This method initiates a special trajectory mode whereby a GPL program can specify incremental changes in position and orientation that are immediately applied to the executing trajectory. When this mode is active, each time that the Trajectory Generator computes a Cartesian set point, it automatically modifies the set point to include the accumulated incremental real-time changes.

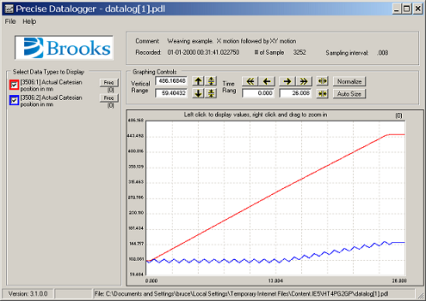

This method can be used to incorporate sensor feedback or to alter a baseline path for special processes. For example, if the tool tip must maintain a specific height as it moves above a distorted surface, input from a height sensor can be used to modify the planned path as the tool is moving. As another example, if the robot is used for welding, a weaving motion can be superimposed on the basic weld path by adding a real-time change that moves back and forth perpendicular to the direction of travel.

When this method is executed, the Attached robot is immediately placed into this special trajectory mode even if a Cartesian motion is currently in progress. Thereafter, any thread can post incremental changes in position (Dx, Dy, Dz) and orientation (Rx, Ry, Rz) that will dynamically alter the planned path. Since these changes are immediately added to the planned path, the GPL program must guarantee that the magnitudes of each change is small to avoid abrupt motions. If no motion is being executed, the changes will alter the stationary position of the robot's tool. If a motion or sequence of motions are being executed, the changes will alter the planned tool path. While this mode is active, only Cartesian motions are permitted. This mode can span an arbitrary sequence of Cartesian motions and continues to operate even when no motion is being executed.

To simplify the use of this method for different applications, the coordinates parameter specifies one of several choices for the coordinate system in which the incremental changes are interpreted and accumulated. To illustrate these alternatives, we will consider the following basic Cartesian motion where the tool orientation is rotated counter-clockwise as the tool tip moves along a straight-line path from p1 to p2.

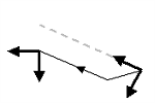

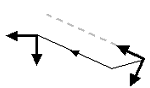

If the incremental changes are specified in World coordinates and are accumulated in World coordinates (World-World mode), incremental changes in position simply shift the entire path and changes in orientation rotate the tool tip about its end point.

|

Position Change |

Orientation Change |

This mode decouples changes in orientation and position and so is conceptually very easy to use. It is analogous to the motions permitted with the Manual Control Pendant's World jog mode.

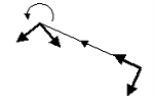

If the incremental changes are specified in Tool coordinates and the incremental changes are accumulated in World coordinates (Tool-World mode), incremental changes in position shift the path in a manner similar to World-World mode, but the shifts are initially evaluated along the instantaneously direction of the tool. However, changes in orientation not only change the orientation of the tool, but also rotate the subsequent direction of the planned path.

|

Position Change |

Orientation Change |

This mode can best be understood if you imagine you are flying the toolP around the workspace. You can slip the tool right or left or move forward or backwards to offset the path. However, if you turn the tool, you are setting it course along a new baseline path and the taught path is relative to this new baseline. This method is analogous to the motions permitted with the Manual Control Pendant's Tool jog mode.

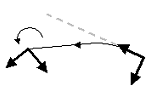

The final method specifies changes in Tool coordinates and accumulates the incremental changes in Tool coordinates (Tool-Tool mode).

|

Position Change |

Orientation Change |

This mode is analogous to dynamically changing the dimension and orientation of the robot's tool. If you change the orientation in this mode, it generates a simple rotation about the tool tip. However, if you change the position, this is equivalent to offsetting the tool and will cause the path to curve if the orientation of the tool changes. If the tool does not change its orientation, incremental changes in position simply shift the path.

The set of coordinate systems to be used are defined by the coordinates parameter as shown in the following table.