This method initiates, changes or terminates a special trajectory mode that computes the instantaneous commanded speed of the attached robot's tool tip and automatically sets the value of an analog output channel (DAC) based upon the computed speed. The trajectory generator computes the tool tip speed each time it evaluates the path set points. This computation takes into consideration all of the characteristics of the trajectory including accelerations, decelerations, motion blending, any reduced speed due to the global test speed set by the Operator Control Panel, real-time path modifications, etc.

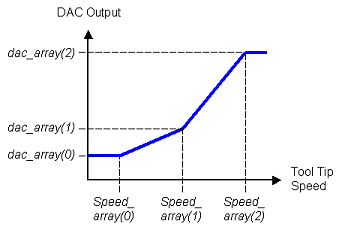

The computed tool tip speed is converted to a DAC value using one or more piecewise linear interpolation segments. If a single segment is specified, a range of speeds are linearly converted to a range of DAC values. Speeds that are less than the lowest value in the speed range are set to the first value in the DAC range. Speeds that are higher than the highest value in the speed range are set to the last value in the DAC range. If two or more linear segments are specified, a piecewise linear relationship between tool tip speeds and DAC values can be represented. The graphic below illustrates how tool tip speeds are converted to DAC values for a sample two segment (n_segments=2) specification.

Once the DAC value is computed by the Trajectory Generator using the piecewise linear specification, the value is sent to the servo code. The servo code interpolates between sequential DAC values at the PID loop evaluation rate and writes the interpolated value to the hardware DAC. This extra level of interpolation ensures that the DAC value will be changed smoothly and accurately. If this method is called with 0 segments specified, this special trajectory mode is terminated and the DAC value is set to 0. This mode can be started, modified and stopped at any time when the robot is idle or moving. However, once started, only Cartesian interpolated motions (e.g. straight-line or circular interpolated) can be executed. There are several Parameter Database values that are important for the operation of the SpeedDAC method.