This module controls a 7-axis robot that consists of all rotary actuators. This configuration is commonly referred to as an "Articulated" robot. Since only 6-axes are generally required to move a robot's gripper to any 3D position with an arbitrary 3D orientation within the workspace of the robot, the 7th axis is redundant with the other degrees of freedom. In fact, for a typical 6-axis articulated robot, a specific gripper position and orientation can often be achieved by eight different sets of axis positions characterized by the Righty/Lefty, Above/Below, and Flip/NoFlip configuration flags. When a 7th redundant axis is added to the robot, it becomes possible to reach a specific gripper position and orientation with an infinite number of axis positions by still specifying Righty/Lefty, Above/Below, and Flip/NoFlip and then arbitrarily altering the position of the redundant axis.

The extra flexibility of the redundant axis can be used to command the robot to reach around obstacles or to avoid singularities in the kinematic equations. However, since the system does not know how to utilize the redundant axis, its position will remain unchanged until the operator or an application program specifically alters it. If the position of the redundant axis is changed during a straight line motion, the system will take into account the instantaneous position of the redundant axis to still have the gripper follow a straight line path.

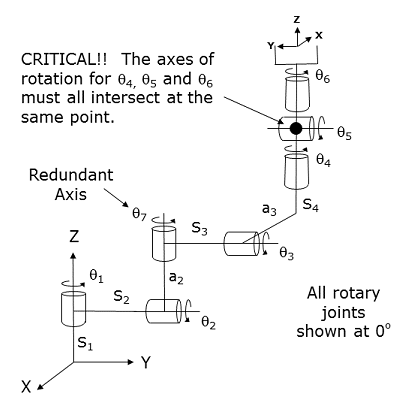

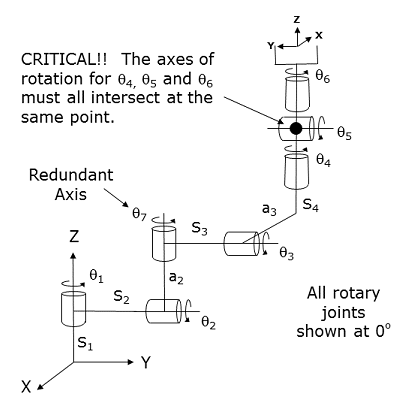

For this robot, the first axis rotates the robot about the World Z-axis. The next two sequentially numbered axes rotate the inner and outer links about horizontal axes (when the redundant axis is at its 0 position). The redundant axis, which is referenced as q7, the 7th logical axis, is physically located between the second and third logical axes and rotates them with respect to each other. The combination of the first three axes and the redundant axis positions the wrist at a desired X, Y, Z location. The final three rotary wrist axes control the orientation of the tool flange relative to the orientation defined by the first three axes and the redundant axis.

Below is a graphical depiction of this kinematic module.

NOTE: For computational reasons, unlike the standard 5/6-Axis Articulated robot kinematic module, there is no horizontal offset between S1 and S2. That is, a1 must always be zero.

Kinematics Module Number and Required Software License

Module number to be entered into the "Robot type" (DataID 116): 20

Required software kinematic license (entered using the web interface panel Utilities > Controller Options if not already installed): Complex Kinematics.

Kinematic Model

| Axis | Optional | Max Range | Description |

|---|---|---|---|

|

1: q1 |

No |

+/- 359.9° |

Rotary axis that rotates the robot about the World Z-axis. A positive change in the axis angle results in a positive rotation about the World Z-axis. The center of this axis' travel can be arbitrarily set, although it is typically centered about 0, 180 or -180 degrees. |

|

2: q2 |

No |

+/- 359.9° |

Rotary axis that rotates the links of the robot about a horizontal axis. When q1 is zero, a positive change in the axis angle results in a positive rotation about the direction of the World Y-axis. The center of this axis' travel can be arbitrarily set, e.g. 0 or 45 or 180 or -135 degrees. |

|

3: q3 |

No |

+/- 359.9° |

Rotary axis that rotates the outer link. When q1 and q7 are zero, a positive change in the axis angle results in a positive rotation about the direction of the World Y-axis. The center of this axis' travel can be arbitrarily set, e.g. 0 or 45 or 180 or -135 degrees. |

|

4: q4 |

No |

+/- 359.9° |

Rotary axis that rotates the wrist about the outer link of the robot. When all of the axes are at their 0 positions, a positive change in this axis angle results in a positive rotation about the direction of the World Z-axis. The center of this axis' travel can be arbitrarily set, e.g. 0 or 45 or 180 or -135 degrees. |

|

5: q5 |

No |

+/- 359.9° but typically set to +/- 179.9° |

Rotary axis that pitches the Tool orientation relative to the outer link of the robot. When all of the axes are at their 0 positions, a positive change in this axis angle results in a positive rotation about the direction of the World Y-axis. The center of this axis' travel can be arbitrarily set, e.g. 0 or 45 or 180 or -135 degrees. |

|

6: q6 |

No |

Unlimited but typically set to +/- 359.9° |

Rotary axis that rotates the end-effector about the Tool Z-axis. A positive change in the axis angle results in a positive rotation about the Tool Z-axis. The center of this axis' travel can be arbitrarily set, although it is typically centered about 0, 180 or -180 degrees. |

|

7: q7 |

No |

+/- 359.9° |

Redundant rotary axis that rotates the outer link of the robot relative to the inner link. When q2 is zero, a positive change in the axis angle results in a positive rotation about the direction of the World Z-axis. The center of this axis' travel can be arbitrarily set, e.g. 0 or 45 or 180 or -135 degrees. |

Parameter Database Values

The following table describes the Parameter Database values that are utilized to configure the kinematic module. Standard motion control parameters such as servo tuning values, limit stops, the homing specification, etc are not included in the table.

| Parameter Database ID | Parameter Name | Description |

|---|---|---|

|

2000 |

Number of axes |

Must be set to 7 |

|

2001 |

Split-axis mask |

Not applicable. |

|

2003 |

Axis mask |

Not applicable. |

|

2005 |

Motor linearity compensation |

Not supported. |

|

2006 |

Robot type special option flags |

Not applicable. |

|

2701 / 2703 |

100% Cartesian speeds and accels |

Value 1: Cartesian 100% linear speed and acceleration of the robot's end-effector measured along any vector in X, Y and Z. |

|

Value 2: Cartesian 100% rotation speed and acceleration of the Tool orientation about the Tool Z-axis. This is normally set to be equal to the joint control values for the 6th axis. |

||

|

Value 3: Cartesian 100% rotation speed and acceleration of the Tool's yaw and pitch orientation. This is normally set to the lesser of the joint control values for the 4th and 5th axes. |

||

|

Value 4: Should be set to 1.0 or some other non-zero value for this module to operate properly. |

||

|

Value 5: 100% rotational speed and acceleration of the redundant axis, q7. This is normally set equal to the joint speed and acceleration of the redundant axis. |

||

|

Values 6-n: Not used. |

||

|

16050 |

Kinematic dimensional constants |

Value 1 (S1): Vertical (Z) offset from the Z=0 plane of the World coordinate system to the height of the axis of rotation of the second rotary axis (q2). Can be arbitrary set by the robot designer to establish the base of the World coordinate system. |

|

Value 2 (S2): Horizontal offset of the second (q2) axis. This is the shortest horizontal distance from S1 to a2. |

||

|

Value 3 (a2): Length of the inner link, the shortest distance from the axis of q2 to that of q3. |

||

|

Value 4 (S3): Offset of the third primary (q3) axis. This is the shortest distance from a2 to a3. When all axes are at their 0 positions, this is the horizontal distance from a2 to a3. |

||

|

Value 5 (a3): Offset of the axis of rotation of q3 relative to the center line of the outer link. This is the shortest distance from the axis of rotation of q3 to the axis of rotation of q4. |

||

|

Value 6 (S4): Length of the outer link measured from the intersection of a3 and S4 to the center of the wrist, e.g. the intersection of the q4, q5 and q6 axes of rotation. NOTE: Any offset from the center of the wrist to the Tool mounting flange or gripper must be specified as part of the robot's Tool property. |

||

|

Values 7-n: Not used. |

||

|

16051 |

Tool set at restart |

When the controller is restarted, this specifies the initial value for the position and orientation of the robot's tool center point relative to the intersection of the wrist joints, q4, q5 and q6. For most simple tools, only the length of the tool needs to be defined by setting this parameter to: 0, 0, tool_length, 0, 0, 0. NOTE: Any offset from the center of the wrist to the Tool mounting flange or gripper must be specified as part of the "tool_length" value. |

|

16052 |

Base set at restart |

When the controller is restarted, this defines how the base of the robot is positioned relative to the World coordinate system. Normally, this parameter is set to 0, 0, 0, 0, 0, 0. |

Robot Configuration ("Config") Parameters

This kinematic module makes use of the following Location Config property flags together with the position of the redundant axis to control how Cartesian positions and orientations are converted to joint angles since multiple sets of joint angles are possible:

GPL_Righty, GPL_Lefty, GPL_Above, GPL_Below, GPL_Flip, GPL_NoFlip, GPL_Single.

Special Compensation

This kinematic module does support "Continuous Turn Axes" for the the last primary rotary axis: q6.

This kinematic module does support "Motor Coupling" to compensate for mechanical coupling that may exist between the axes. The first motor is uncoupled and the second and third primary motors that drive q2 and q3 are coupled by a 2x2 matrix. The fourth, fifth and six motors are coupled by a 3x3 matrix. Lastly, the motor for the redundant axis, q7, is uncoupled.

This kinematic module does not support "Linearity Compensation" or "Split-Axis Control".

This kinematic module does support a subset of the full "Dynamic Feedforward" compensation (DFF). For this robot, the DFF compensation only provides position independent gravity compensation and it does not generate feedforward terms to counteract dynamic effects due to accelerations and velocities.

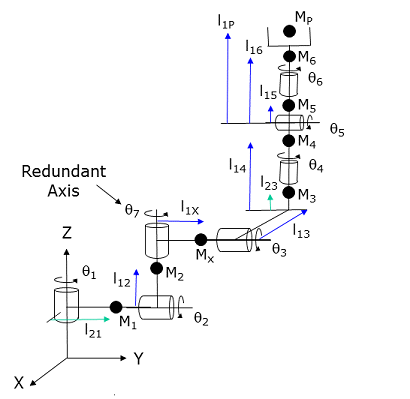

The following diagram and table illustrate how the DFF constants are defined for this robot.

Parameter Database ID Parameter Name Values 16066

Dynamic feedforward enable

1

16067

Dynamic feedforward mass, kg

M1, M2, MX, M3, M4, M5, M6, Mp

16068

Dynamic feedforward COM l1, mm

0, l12, l1X, l13, l14, l15, l16, l1p

16069

Dynamic feedforward COM l2, mm

l21, 0, 0, l23, 0, 0, 0, 0

16070

Dynamic feedforward rated torque, N-m

<filled in based on axis drives>

16071

Dynamic feedforward default %payload

Any value from 0 to 100

16072

Dynamic feedforward motor/gear inertia, kg-mm^2

Not utilized

Mp and l1p define the maximum mass of the payload and the position of this mass relative to the pitch axis. M6 and l16 represent both the tool mounting flange and the tool.

Additional Considerations

This kinematic module does not utilize the Custom Kinematic Parameters accessed by Robot.Custom.

To move the independent redundant axis, q7, during the next motion of the primary axes to a Cartesian Location, execute the Move.Extra method. If this method is not invoked and the next motion is to a Cartesian Location, the position of the redundant axis will not be altered. The following illustrates the use of Move.Extra.

Move.Extra(30) ' Move redundant axis to 30 deg during next motion

Move.Loc(Location.XYZValue(300,0,100),pf1) ' Move primary arms toolThe redundant axis can also be simultaneously moved by performing a motion to an Angles Location. The value of the location will explicitly define the final position for all axes.