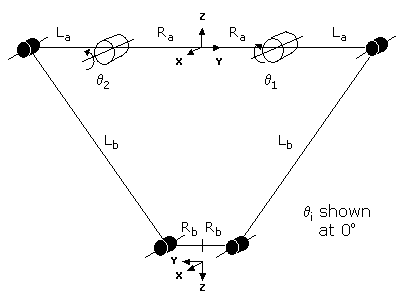

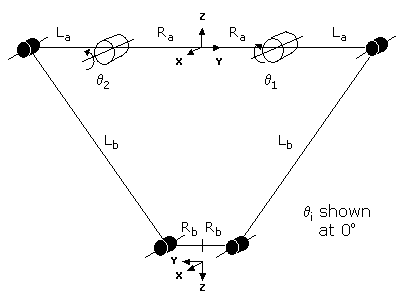

This module controls a 2 degree-of-freedom planar "Delta" parallel link mechanism. This device translates its tool platform in a fixed orientation with respect to the World Y and Z axes. That is, the tool of this robot moves in the same manner as the tool of a YZ Cartesian robot. The tool can translate right and left and vertically, but cannot be rotated. This mechanism has the advantage of being extremely fast for light payloads. Since the motors are fixed, only light weight rods are needed to position the tool platform. The disadvantage of this geometry is that the working volume has very little height and has a very flat, elliptical shape.

To move the tool platform, the two motors are rotated about their axes. Each motor drives a link that moves a secondary link up and down. The two links for each motor are connected by a hinged joint. The bottom ends of the secondary links are connected to the tool platform. In order for the tool platform to maintain a fixed orientation, typically one pair of links is implemented as a pantograph linkage. The combination of the two motor positions dictates the Y and Z position of the center of the fixed orientation tool platform.

This configuration is a variation of the 3/4-DOF Delta robot design that is very popular.

Kinematics Module Number and Required Software License

Module number to be entered into the "Robot type" (DataID 116): 18

Required software kinematic license (entered using the web interface panel Utilities > Controller Options if not already installed): Advanced Kinematics.

Kinematic Model

Axis Optional Max Range Description 1: q1

No

Approximately

-55° to +110°Two identical rotary axes that drive links connected to vertical links that are attached to the tool platform. A positive change in an axis moves its corresponding links lower. The zero position of each axis is at the angle where the center of rotation of the hinge between its first and second links is at the same height as the center line of the motor. The travel of each axis is limited due to mechanical "lock-up" positions in the mechanism. The exact limit on the travel is a function of the link lengths.

2: q2

No

Parameter Database Values

The following table describes the Parameter Database values that are utilized to configure the kinematic module. Standard motion control parameters such as servo tuning values, limit stops, the homing specification, etc are not included in the table.

Parameter Database ID Parameter Name Description 2000

Number of axes

Must be set to 2.

2001

Split-axis mask

Not applicable.

2003

Axis mask

Not applicable.

2005

Motor linearity compensation

Not supported.

2006

Robot type special option flags

Not applicable.

2701 / 2703

100% Cartesian speeds and accels

Value 1: Cartesian 100% linear speed and acceleration of the robot's end-effector measured along any vector in Y and Z.

Value 2: Cartesian 100% rotational speed and acceleration of robot's end-effector. Not used for this module.

Values 3-n: Not used.

16050

Kinematic dimensional constants

Value 1 (S0): Vertical (Z) offset of the center point between the motors, relative to the origin of the World coordinate system. This value can be arbitrary set by the robot designer to establish the height of the World coordinate system relative to the top of the robot.

Value 2 (Ra): Half the distance between the motors.

Value 3 (Rb): Half the distance between the lower link connection points on the tool mounting plate.

Value 4 (La): Length of the link that connects one of the motors to its vertical links, measured from the axis of the motor to a hinge joint of the vertical links.

Value 5 (Lb): Length of the vertical links measured from the top hinge joint to the bottom hinge joint.

Value 6: Set to 0 for compatibility with future enhancements.

Values 7-n: Not used.

16051

Tool set at restart

When the controller is restarted, this specifies the initial value for the position and orientation of the robot's tool center point relative to the tool mounting plate and the theta axis, q4. For most simple tools, only the length of the tool needs to be defined by setting this parameter to: 0, 0, tool_length, 0, 0, 0.

16052

Base set at restart

When the controller is restarted, this defines how the base of the robot is positioned and oriented relative to the World coordinate system. Normally, this parameter is set to 0, 0, 0, 0, 0, 0.

Robot Configuration ("Config") Parameters

This kinematic module makes use of the following Location Config property flags to control how Cartesian positions and orientations are converted to joint angles:

None

Special Compensation

This kinematic module does not support "Continuous Turn Axes".

This kinematic module does not support "Motor Coupling", "Linearity Compensation" or "Split-Axis Control".

This kinematic module does not support "Dynamic Feedforward" compensation (DFF).

Additional Considerations

This kinematic module does not utilize the Custom Kinematic Parameters accessed by Robot.Custom.

This kinematic module does not have any extra, independent axes so Move.Extra has no affect.